How to Choose the Best Cardboard Boxes for Your Shipping Needs

When it comes to shipping, choosing the right cardboard boxes is crucial. According to a recent report from Smithers Pira, the global demand for cardboard packaging will reach 400 billion square meters by 2025. This staggering growth highlights the importance of selecting boxes that fit specific shipping needs. Industry expert Dr. Emily Carter emphasizes, "The right cardboard box can significantly reduce shipping damages."

Damage during transit can lead to costly replacements. A study by the Packaging Institute found that 25% of products suffer damage due to inadequate packaging. Businesses often overlook the significance of box selection. Standard sizes may seem convenient, but they often lead to inefficiencies. A well-fitted box can save material and reduce costs.

Companies need to consider factors carefully. Box strength, size, and material type play essential roles. However, many businesses still ignore the long-term benefits of investing in quality cardboard boxes. There is a balance to strike between cost and durability. Selecting the right box requires thoughtful reflection on shipping demands and environmental impact.

Understanding Different Types of Cardboard Boxes for Shipping

When selecting cardboard boxes for shipping, understanding the types available is crucial. There are various styles and designs tailored for specific needs. Regular slotted containers, or RSC, are among the most common. They are versatile and economical. You will frequently find these boxes in warehouses. Their simple design is effective, but they may not always suit fragile items.

Another type is the die-cut box. These boxes are custom-made to fit specific products. They provide a snug fit and added protection. However, getting the dimensions right can sometimes be challenging. A poorly fitting box can result in damage during transit. Additionally, there are heavy-duty boxes for larger, heavier items. These boxes are thicker and more durable. They can hold significant weight, yet they may be overkill for lighter shipments.

Considerations like weight, fragility, and the shipping environment are important. A box that works for one product may not work for another. You might prefer a box that is easy to assemble. However, a simpler design may not offer sufficient protection for delicate goods. Take time to reflect on the needs of your shipment. Finding the right balance is essential for a successful shipping experience.

How to Choose the Best Cardboard Boxes for Your Shipping Needs

| Box Type | Material | Strength Rating | Best Use Case | Dimensions (inches) |

|---|---|---|---|---|

| Regular Slotted Container (RSC) | Multi-wall corrugated | Bursts at 32 ECT | General shipping and storage | 12 x 12 x 12 |

| Die-Cut Box | Single-wall corrugated | Bursts at 24 ECT | Custom shapes and sizes | Varied |

| Box with Partition | Heavy-duty corrugated | Bursts at 44 ECT | Fragile items and electronics | 16 x 12 x 12 |

| Flat Pack Box | Heavy-duty cardboard | Bursts at 32 ECT | Flat or low-profile items | Various Available |

| Mailer Box | Single-use corrugated | Bursts at 32 ECT | E-commerce and retail items | 14 x 10 x 2 |

Evaluating Box Strength and Durability for Safe Shipping

When shipping products, selecting the right cardboard box is crucial. The strength of a box is determined by its materials and construction. Look for boxes made from high-quality, thick cardboard. Double-walled boxes offer enhanced strength for heavier items. This can prevent damage during transit, which is essential for maintaining customer satisfaction.

Durability matters too. Consider how the box will be stored and transported. Boxes exposed to varying temperatures and humidity may weaken. A water-resistant coating can help. Furthermore, check for proper seals and secure flaps. A flimsy seal can lead to unfortunate accidents. Small details like these often go unnoticed but can impact the integrity of the package.

Not all boxes are created equal. You might assume that a standard box will suffice for all shipments. However, that can be a costly mistake. Take time to test your boxes under real-world conditions. This reflection can save you from future shipping nightmares. Don't overlook the importance of choosing the right box; it might be the difference between an intact delivery and a disgruntled customer.

Selecting the Right Box Size for Your Products

Choosing the right box size for your products can be tricky. A box that’s too large can lead to high shipping costs and damage during transport. On the other hand, a small box may cause your items to be crushed or the packaging to be unprofessional. It’s crucial to measure your products accurately before selecting a box.

Consider the dimensions of your items. Length, width, and height matter. Aim for a snug fit, allowing for padding materials but not too much extra space. Think about the weight, too. Heavier items require sturdier boxes. If you use boxes that collapse under pressure, you're likely to receive complaints.

Don’t forget to include the packing materials in your calculations. Bubble wrap or packing peanuts take up space. A box that fits snugly around your items may end up being too tight once they’re padded. Reflect on past shipments. Did any items arrive damaged? If so, you might need to rethink your box sizes. Constantly evaluate and adjust your choices to ensure safe deliveries.

Considering Additional Features for Enhanced Protection

When selecting cardboard boxes for shipping, extra features can make a significant difference. Look for boxes with reinforced corners. These areas take the most impact during transit. Using double-walled boxes can provide additional strength. They are ideal for heavier items. A well-padded box helps protect fragile goods from breakage.

Sealing options are also essential. Consider boxes that allow for secure sealing. Water-resistant options are available, as well. They guard against moisture, which could cause damage. Air-filled cushions or foam inserts can be beneficial for smaller items. They ensure products stay in place and are safe from shifting.

However, some features may not be necessary for every shipment. It's essential to analyze your needs. Maybe a plain box suffices for robust items. Reviewing your shipping practices can lead to better choices. Reflect on past damages to narrow down what works best for you. Paying attention to details will enhance your shipping efficiency.

Best Cardboard Boxes for Shipping Needs

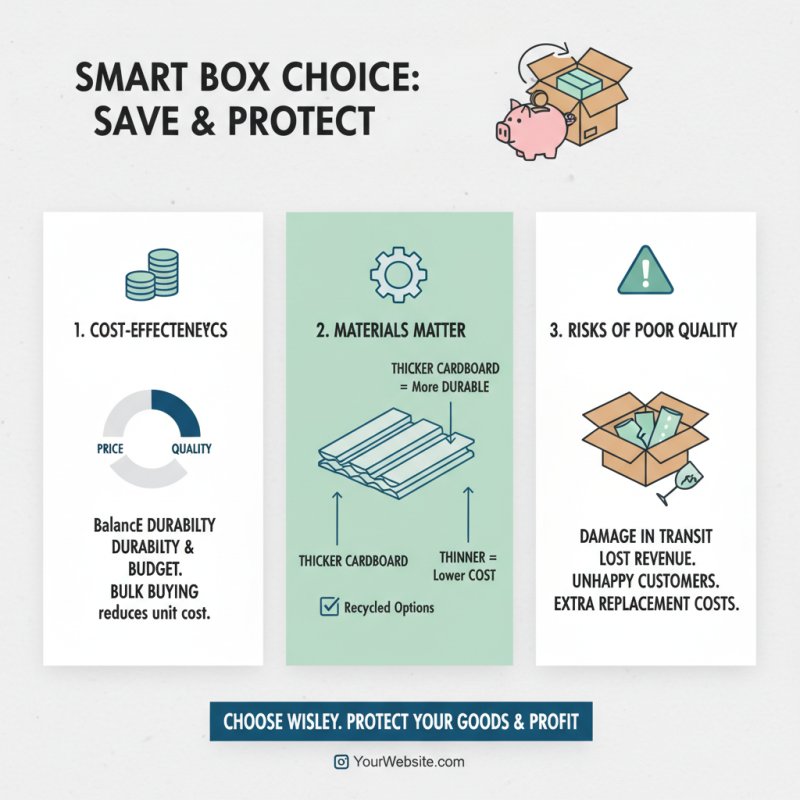

Cost-Effectiveness: Balancing Quality and Price for Shipping Boxes

When selecting cardboard boxes, cost-effectiveness is crucial. You want quality boxes that don't break the bank. Think about the materials used. Thicker cardboard often offers better durability but may come at a higher price. Balancing this can be tricky. If you choose low-quality boxes, expect problems. Your items could get damaged in transit. That's frustrating and costly.

Also, consider the size of boxes. Smaller boxes might be cheaper and reduce shipping costs. However, packing items tightly can lead to damage. Oversized boxes can inflate shipping expenses. Finding the right fit is a challenge. You may need to experiment with different sizes. Track your expenses and see what works best for your needs.

Understand the importance of bulk purchasing. Buying in larger quantities can sometimes lower the per-box cost. But, this requires upfront investment. You may end up with excess boxes. Evaluate your shipping volume regularly. This will help you make informed decisions. Reflect on your choices so you can optimize your shipping process.

Related Posts

-

2025 How to Choose Custom Printed Boxes for Your Business Needs

-

Why Custom Made Boxes Are Essential for Your Packaging Needs

-

Top 10 Benefits of Using Corrugated Boxes for Shipping and Storage

-

Why Custom Printed Mailer Boxes Are Essential for Your Business Success

-

Top Custom Shipping Boxes Ideas to Enhance Your Packaging Experience

-

What are Custom Mailer Boxes and How Can They Benefit Your Business?