How to Choose the Right Shipping Boxes for Your Business Needs?

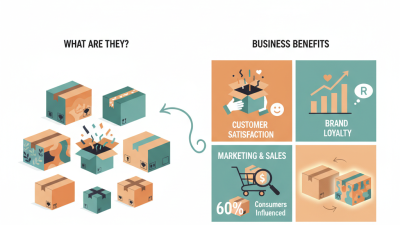

Choosing the right shipping boxes is crucial for businesses of all sizes. The demand for e-commerce has surged, with reports indicating a 44% increase in online sales over the past year. As a result, the packaging industry is evolving rapidly. Selecting appropriate shipping boxes can significantly impact shipping costs and product safety.

More than 30% of businesses report damages during transit related to poor packaging. This highlights the importance of durable and well-fitted shipping boxes. A study found that 57% of customers prefer brands that use eco-friendly packaging. Sustainable shipping boxes can enhance brand loyalty and customer satisfaction.

However, businesses often overlook specific dimensions and materials suitable for their products. Miscalculations can lead to increased shipping fees and higher return rates. The challenge lies in balancing cost, quality, and environmental impact when choosing shipping boxes. Reflection on these aspects can drive better decisions in packaging strategies.

Understanding Your Shipping Requirements Based on Product Type

Shipping requirements vary greatly based on product type. Fragile items need extra care and cushioning. Reports show that damaged goods can increase shipping costs by up to 30%. It’s vital to select the right box size and material. A box that is too large can lead to movement during transit, which risks damage. In contrast, an oversized box can inflate shipping costs unnecessarily.

Products like electronics often require specialized packaging. Using anti-static materials is key to prevent issues during shipping. A study indicates that 70% of customers are influenced by packaging quality. If your products are organic or perishable, temperature-controlled shipping boxes become essential. They help maintain freshness, but costs may rise significantly.

Understanding your audience is crucial. Some consumers prefer eco-friendly packaging even if it means higher prices. The latest surveys indicate that 45% of shoppers consider sustainability essential in their purchasing decisions. Evaluating your shipping options regularly can uncover gaps. Many businesses overlook the hidden costs of improper packaging. Reviewing these aspects may save money and improve customer satisfaction.

Evaluating Different Shipping Box Materials for Durability

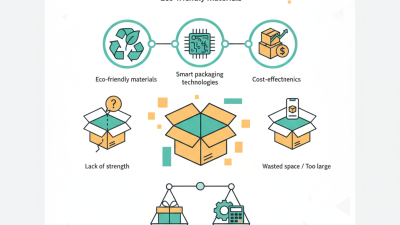

Choosing the right shipping box materials is crucial for ensuring product safety during transit. Various materials offer different levels of durability, impacting delivery performance. For example, corrugated cardboard remains a popular choice due to its lightweight yet strong structure. According to a report by Smithers Pira, over 80% of products shipped globally use corrugated boxes, highlighting their importance.

Plastic containers are another durable option. They are resistant to moisture and offer excellent protection against physical shocks. Industry data shows that plastic shipping containers can withstand impacts better than cardboard, reducing damage rates by up to 30%. However, they are often more expensive, which can be an obstacle for small businesses.

Wooden crates provide superior strength for heavy or oddly shaped items. They can support significant weight but come with a heavier environmental footprint. Improper use can lead to wasted resources or ineffective shipping. A common challenge is finding the right balance between cost and durability. Each choice has its pros and cons, requiring thoughtful consideration of your specific business needs and product types.

Determining the Right Box Size for Efficient Packing

Choosing the right box size can make a huge difference in shipping. A well-fitted box ensures products are secure during transit. If the box is too large, items may shift around. This can lead to damage and unhappy customers. Conversely, a box that’s too small might crush or compromise the product. It’s essential to find that balance for efficiency.

When determining box size, consider the dimensions of your products carefully. Measure each item before selecting a box. Think about how many items you plan to ship together. Packing materials, like bubble wrap or packing peanuts, also take up space. Sometimes, it may seem like a box that is slightly larger could be a good choice. But in practice, unused space can lead to higher shipping costs. One size may fit most, but not all.

Reflecting on past shipments can provide insights. Did items arrive damaged? Were they securely packed? Each answer can guide future box choices. Optimizing box size contributes to cost-effectiveness and customer satisfaction. Finding the right fit may take time. It’s worth re-evaluating your choices frequently.

Considering Cost-Effectiveness in Shipping Box Selection

When choosing shipping boxes, cost-effectiveness is key. Analyze your budget carefully. Consider how much you can spend on shipping materials. The goal is to find boxes that protect your products without overspending. Cheap boxes can lead to damage. Damaged goods mean unhappy customers.

Think about different sizes and types of boxes. Standard sizes are often more affordable. Custom-sized boxes might be necessary but can increase costs. You might think that using larger boxes saves money. However, oversized boxes can lead to wasted space. This can increase shipping fees.

Evaluate your order volume and frequency. If you ship regularly, bulk purchasing could save money. But, do you really need to store extra boxes? Space could become an issue. Be mindful of where you'll keep the boxes. Choosing the right size and type is an ongoing challenge. Reflect on your choices often to improve efficiency and cost management.

Exploring Eco-Friendly Shipping Box Options for Sustainability

When considering eco-friendly shipping boxes, it's crucial to explore various sustainable options. Recycled cardboard is a popular choice. It reduces waste and has a lighter carbon footprint. Using recycled materials can cut down on resource use while maintaining box strength. Each box made from recycled content helps the planet.

Another option is biodegradable materials. These boxes break down naturally, leaving no harmful residues. Companies could consider these if they want to emphasize environmental responsibility. However, there may be limitations in terms of durability. Some biodegradable options might not withstand long-distance shipping. Find out the right balance for your shipments.

Tips: Choose boxes that fit your products well. An oversized box wastes materials and can cause damage. Also, consider sourcing from local suppliers to minimize transport emissions. Regularly assess your packaging needs. Adjust as necessary to remain sustainable yet effective.

Shipping Box Options for Sustainable Business Practices

This chart illustrates the preferences for various eco-friendly shipping box materials among businesses aiming for sustainability. The data reflects the demand for different types of materials used in shipping boxes over the last year.

Related Posts

-

Top Custom Shipping Boxes Ideas to Enhance Your Packaging Experience

-

What are Custom Mailer Boxes and How Can They Benefit Your Business?

-

2026 Best Shipping Boxes for Your Packaging Needs?

-

How to Create Personalized Shipping Boxes for Your Business Essentials?

-

2026 Best Custom Mailer Boxes for Your Packaging Needs?

-

How to Choose the Best Cardboard Boxes for Your Shipping Needs