10 Tips for Choosing the Best Custom Corrugated Boxes for Your Business?

In today's competitive market, custom corrugated boxes have become essential for businesses of all sizes. According to a recent study by Smithers Pira, the global corrugated packaging market is expected to reach $310 billion by 2024. This growth underlines the importance of selecting the right packaging solutions. The right custom corrugated boxes can enhance brand visibility and improve supply chain efficiencies.

Choosing custom corrugated boxes is not just about aesthetics. Strong packaging protects products during shipping. Poor choices can lead to damage and customer dissatisfaction. In fact, a study from the Packaging Association found that approximately 30% of consumers have received damaged products. This highlights the need for careful selection.

Investing time in choosing custom corrugated boxes is crucial. Factors like strength, size, and design directly impact customer experience. Brands often overlook the importance of sustainability too. A survey by Nielsen revealed that 66% of global consumers are willing to pay more for sustainable brands. Thus, packaging not only impacts your bottom line but also your brand image.

Factors to Consider for Material Selection in Custom Corrugated Boxes

When selecting materials for custom corrugated boxes, several critical factors should be considered. The right choice can influence not just product protection, but also shipping costs and environmental impact. According to a 2022 industry report, about 70% of businesses have switched to eco-friendly packaging materials, as consumers increasingly prefer sustainable options.

One tip is to assess the weight of your products. Lighter materials can reduce shipping costs. For fragile items, opt for double-wall corrugated boxes. They offer extra protection compared to single-wall options. You may also want to choose materials with a higher burst strength, which can withstand rough handling. A report indicated that around 30% of damages occur during transit.

Another crucial aspect is moisture resistance. If your products are sensitive to humidity, consider coated corrugated boxes. These are designed to protect contents from water damage. While the financial investment may be higher, the potential to prevent product losses can outweigh the costs. Always think about your target market’s expectations. Packaging choices can enhance brand perception.

Finally, experimenting with different designs can yield unexpected benefits. Many businesses overlook the importance of in corrugated box selection. Unique designs can capture consumer attention and drive sales.

Understanding the Impact of Box Design on Product Protection and Branding

The design of custom corrugated boxes plays a significant role in product protection and branding. A well-designed box can cushion products during shipping, preventing damage. For instance, incorporating adequate padding and structural integrity into the design can enhance protection. Shoppers are often drawn to visually appealing packaging, as it reflects the quality of the product inside. A thoughtful design contributes to a positive unboxing experience.

Branding goes beyond visuals. Colors and logos are crucial, but so are the materials used. The texture of the box can create an emotional connection with consumers. Too often, businesses overlook the tactile experience. A plain cardboard box may fail to convey your brand's values. On the other hand, custom finishes can set your product apart. Consider the message that your packaging delivers about your brand.

Incorporating unique design elements can also help your boxes stand out on retail shelves. However, it's imperative to avoid being overly complex. Simplicity can sometimes lead to better recognition. Reflecting on your designs can help refine your branding strategy. Don't shy away from experimenting; not every attempt will resonate. Embrace failures as learning opportunities. Ultimately, your custom corrugated boxes should protect your product while enhancing your brand identity.

Impact of Box Design on Product Protection and Branding

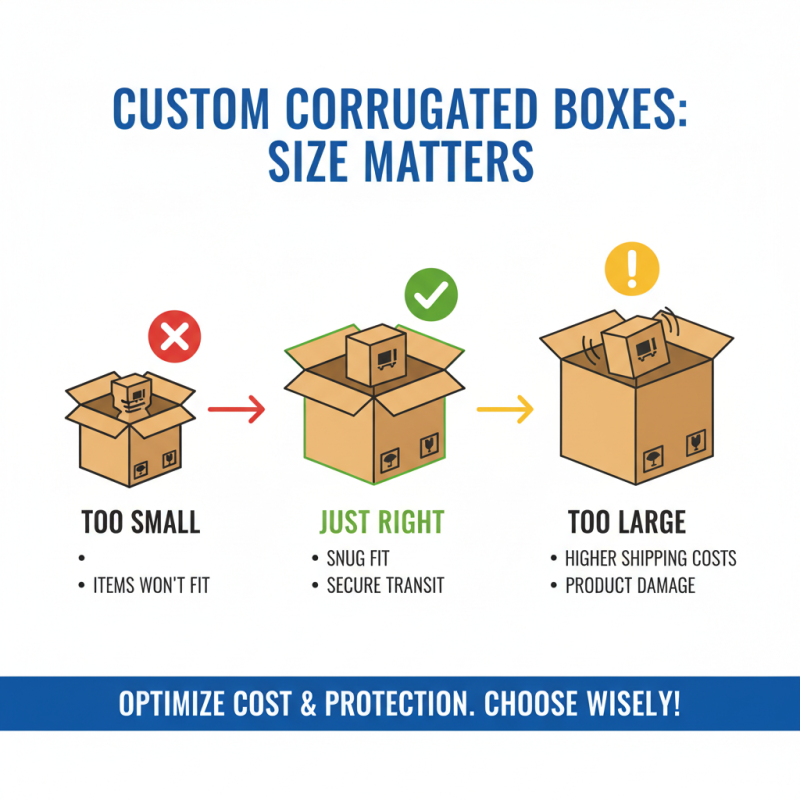

Evaluating Size and Dimensions to Optimize Shipping and Storage Efficiency

When choosing custom corrugated boxes, evaluating size and dimensions is crucial. The right dimensions ensure that your products fit snugly inside, preventing movement during transit. Boxes that are too large can lead to increased shipping costs and product damage. On the other hand, overestimating size can leave you with inadequate space for your items.

Measuring your products carefully is essential. Think about the height, width, and depth of each item. Consider adding extra space for cushioning materials like bubble wrap or packing peanuts. The efficiency of your storage also depends on optimal sizing. Boxes that stack well save space in warehouses and transport vehicles. However, mistakes can lead to waste. For instance, boxes that don't fit onto shelves can cause chaos and frustration.

Reflecting on your dimensions may reveal the need for adjustments. Many businesses overlook packaging size until an issue arises. Regularly reassessing your needs can save future headaches. Remember, perfect sizing is both an art and a science. The goal is to find the sweet spot that works for both shipping and storage.

Sustainability Trends: Choosing Eco-Friendly Options for Your Packaging Needs

Sustainability has become a crucial consideration in packaging. Choosing eco-friendly custom corrugated boxes is essential for businesses. These boxes can reduce environmental impact. They can be made from recycled materials. This choice aligns with growing consumer demand for sustainable products.

When selecting corrugated boxes, think about the material. Opt for those made from 100% recycled content. This promotes a circular economy and supports sustainability. Next, consider the thickness. Thicker boxes can protect products better but might use more resources. A balance is important.

Another tip is to evaluate printing options. Use vegetable-based inks or water-based inks. They are less harmful to the environment. Furthermore, ensure the boxes are easy to recycle. Avoid using excessive adhesives. Streamlining the design can reduce waste. Reflect on your packaging choices. Are they promoting sustainability? It's worth the effort.

Cost Analysis: Balancing Quality and Affordability in Custom Box Production

When considering custom corrugated boxes, cost analysis is crucial. Finding the right balance between quality and affordability can be challenging. High-quality materials and innovative design often come with a higher price tag. However, cheap options may lead to issues like damage during shipping. Businesses need to weigh the pros and cons carefully.

It's easy to be tempted by lower prices. Yet, this can result in hidden costs down the line. Damaged goods lead to customer dissatisfaction. Often, it’s better to invest in quality upfront. Strong boxes can protect products and enhance your brand image. While the initial cost may be higher, the long-term savings can be significant. Quality packaging can reduce product returns and increase customer loyalty.

Balancing quality and affordability requires reflection. Each business has unique needs and budgets. It may be beneficial to test samples from different manufacturers. Assessing durability and design is essential. Past experiences also shape decisions. Prioritize long-term value over short-term savings. Engage with suppliers openly to discuss potential trade-offs.

Related Posts

-

Top 10 Custom Product Boxes You Need for Your Business Success

-

Top Custom Shipping Boxes Ideas to Enhance Your Packaging Experience

-

2025 How to Choose Custom Printed Boxes for Your Business Needs

-

Why Custom Made Boxes Are Essential for Your Packaging Needs

-

Why Custom Printed Mailer Boxes Are Essential for Your Business Success

-

What are Custom Mailer Boxes and How Can They Benefit Your Business?